Car Lifts vs. Jack Stands

Car lifts are mechanical devices—often hydraulic—that raise an entire vehicle off the ground. They are common in professional shops and dealerships, though compact versions exist for home use. By contrast, jack stands are engineered supports that do not lift a car on their own; instead, they provide a stable resting point after a vehicle has been raised with a jack. In practice, a floor jack or bottle jack first lifts the car at factory-specified points, and then jack stands are placed under reinforced frame or suspension points to hold the weight.

Unlike a lift, jack stands are portable and rely on the user to manually position and lock them. Together, these tools allow safe access under a vehicle: the lift does the heavy lifting, while the stands safely support the vehicle once it's aloft.

Popular Types of Car Lifts

Two-post lifts: These have two vertical posts on either side of the vehicle. Each post has two adjustable arms that lift the car at its frame (often at the rocker panels). Two-post lifts come in symmetrical (arms equal length, vehicle centered) and asymmetrical (arms of unequal length, allows posts to be slightly forward) designs. They use powerful hydraulics and synchronized chains or cables, and are space-efficient and common in garages.

Four-post lifts: A four-post lift has four vertical posts and long runways for the wheels. The vehicle simply drives onto the runways, and the entire car is lifted. Because of the extra posts and runways, these lifts are very stable and can handle heavier loads. They must be bolted to a concrete floor and require more space, but they allow very high lifting and easy full-length access under the car. Four-post lifts are popular when high weight capacity or long-duration storage (like parking lifts) is needed.

Scissor lifts: These lifts use a set of crossed arms (like scissors) under the vehicle's undercarriage. When hydraulics extend the arms, the car rises vertically. Scissor lifts usually have a lower maximum height and capacity than post lifts, but they take up less floor space. Some scissor lifts are portable or built into a floor recess. They are often chosen for budget-conscious home mechanics or smaller service bays, since they are generally less expensive and occupy a smaller footprint.

Different Types of Jack Stands

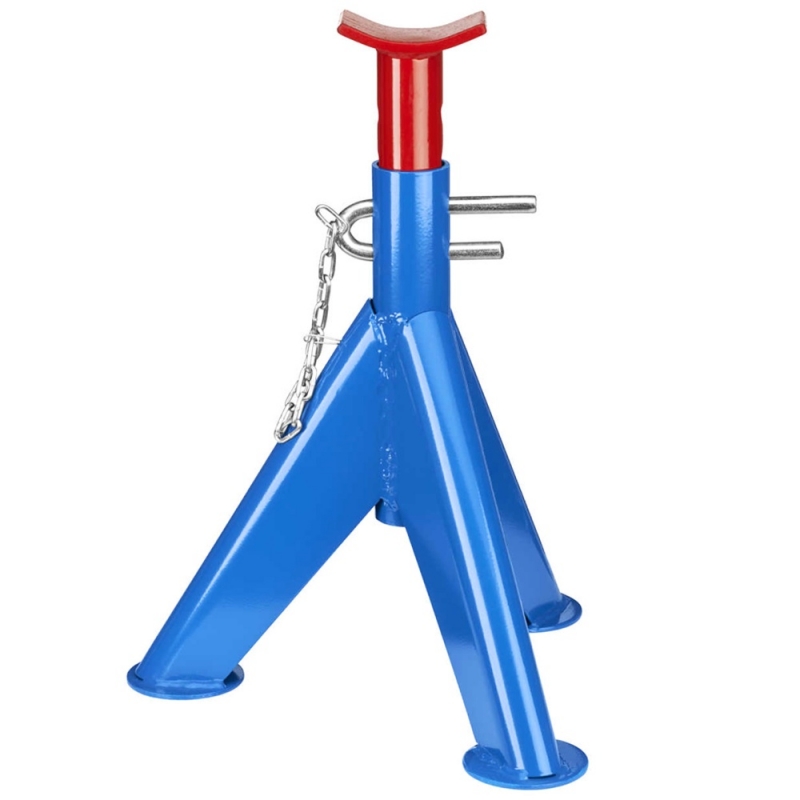

Pin-lock (pin-jack) stands: These are simple, sturdy stands with a post that has multiple height slots. You pull a steel pin to set the desired height and then reinsert it through the aligned holes. Pin-lock stands are very strong and popular for heavy-duty use because the pin reliably holds the load.

Ratchet-lock stands: These stands use a toothed ratchet bar and pawl. You raise the stand (often by pulling up on the bar) and it automatically clicks into the next notch, locking in place. To lower, you release the locking lever. Ratchet stands are quick to adjust, but they rely on the pawl for holding force, so they require caution (avoid striking the release lever while under load).

Screw-lock stands: With these stands, a large threaded center column is turned by a handle to raise or lower the saddle. The weight of the vehicle compresses the threads to hold it. Screw stands have no extra pins or latches; their threaded screw is the only locking mechanism. They tend to be very robust and allow fine height adjustments, but adjustments take more time and the safety depends entirely on the screw's grip under load.

Long-leg (high-clearance) stands: These are heavy-duty stands with extended leg length, designed for very tall vehicles like trucks or buses. Some have built-in floor jacks to first raise the axle before placing it on the stand. Others even have wheels for easier positioning. They give maximum lift height but of course require more clearance and a higher lifting point.

Main Differences Between Lifts and Stands

Mechanism: Car lifts actively raise the vehicle using hydraulics or motors, whereas jack stands are passive supports. In other words, a lift does the lifting, but a jack stand only holds the car once it's already up. For example, NAPA explains that jack stands “do not lift vehicles” but provide a fixed safe support, whereas lifts raise the vehicle to a desired height.

Installation and Mobility: Lifts are usually fixed installations that require a reinforced floor (like a concrete slab) and sufficient ceiling height. For instance, installing a typical two-post or four-post lift in a home garage demands at least a 3.5-inch concrete slab and 8–13 foot ceiling clearance. By contrast, jack stands are portable: they can be carried anywhere and used on any flat surface (garage floor, driveway, etc.) without modification.

Capacity and Height: Lifts generally offer higher lifting capacity and vertical travel. A heavy-duty four-post lift can support very heavy vehicles and raise them very high for full undercar access. Jack stands, while rated for weight (commonly 2–6 tons), are limited by their height and by the need to use them in sets (typically at least two, one on each side or axle). A lift lets you work on the entire vehicle at once, whereas stands give you partial support (often one end or side at a time) unless you use four stands.

When to Use a Car Lift or a Jack Stand

Use jack stands whenever you need to work under the vehicle in a non-commercial setting or for a shorter task. They are ideal for DIY maintenance (oil changes, brake work, suspension repair, etc.) where you only need to raise one end or two wheels. As a safety rule, always plan to use stands (or ramps) rather than relying on a jack alone. For most home users and emergencies (like changing a flat tire in the garage), a hydraulic floor jack with a pair of jack stands is sufficient and cost-effective. In fact, NAPA warns that using jack stands drastically reduces the risk of injury compared to using a jack only.

Use a car lift when you need frequent access under the vehicle, want to work on it entirely at once, or need a higher lift height. For example, auto shops use lifts to speed up repetitive tasks (tire changes, diagnostics, exhaust and transmission work) because a lift can raise the whole car quickly and allow access on all sides. Even for home enthusiasts, there are compact consumer lifts designed for the garage, but these still require a permanent installation. Choose a lift if your projects involve heavy-duty repairs (engine or transmission removal, major suspension work) or if you have multiple vehicles to service. In general, short tasks or occasional work are more practical with stands, while full-service or professional work is more efficient with a lift.

How to Safely Use a Car Lift

1. Always follow the lift manufacturer's instructions and safety guidelines. Before using the lift, verify that it's properly installed and level, and that its rated capacity exceeds the vehicle's weight. Inspect all components (cables, chains, hydraulic hoses, locking mechanisms) to ensure they are intact and functioning. Clear the area of obstructions. Drive or position the vehicle so its center of gravity is between the posts, then align the lift arms or platforms with the vehicle’s factory lift points. Engage the adapter pads firmly against the frame or pinch weld.

2. Raise the vehicle slowly and watch for any shifting; if the car seems unbalanced, stop and recheck the arm placement. Once raised to the desired height, engage the lift's mechanical locks or safety catches before relying on it. Do not work under a car that is only held by hydraulic pressure – always lock it in place with the lift's safety latch. Only then is it safe to go underneath. When lowering, first lift the car slightly to disengage the locks, then lower slowly to the ground. In every step, ensure the vehicle remains stable and the lift operates smoothly.

How to Safely Use Jack Stands

1. Safety with jack stands starts with preparation. Always park the vehicle on level ground, engage the parking brake, and chock the wheels that will remain on the ground. Before jacking up the car, consult the owner's manual to find the reinforced lift points on the frame or pinch welds. Position the hydraulic jack under this point and raise the vehicle evenly.

2. Next, place jack stands under the frame at these same lift points (or near the jack point). Adjust each stand to the same height and lock it securely (inserting the pin or tightening the screw, as applicable). Then lower the vehicle slowly onto the stands by carefully releasing the jack, one stand at a time. Make sure the car's weight is resting solidly on all stands. It's recommended to use at least two stands (one under each side of an axle) for any section of the vehicle being lifted. Once the car is supported, give it a gentle nudge to confirm stability. Only with all weight on the stands and no load on the jack is it safe to work underneath. When the job is done, raise the car slightly with the jack, remove the stands, and then lower the vehicle fully.

Final Thoughts

Lifting a vehicle safely requires understanding the tools and following proper procedures. Car lifts and jack stands each have their place: lifts provide power and convenience for major work, while stands offer flexibility and low cost for routine jobs. The key is always to respect the weight of the vehicle and the limitations of your equipment. Use redundant supports, inspect your gear, and never take chances under a raised car. By choosing the right equipment for the job and using it correctly, you can work under your vehicle with confidence and safety.

For those in need of reliable lifting equipment, consider suppliers like our Winsen – known for quality car lifts and sturdy jack stands across a range of capacities. With the right gear and safe practices, you can tackle automotive maintenance effectively and securely. Feel free to contact us!