This article gives 8 practical, easy-to-follow maintenance tips. They will help you keep your bottle jack working smoothly, extending its life.

1. Inspect and Refill Hydraulic Oil Regularly

Hydraulic oil is the lifeblood of the bottle jack. Over time, particles, moisture, and air can accumulate, reducing lifting efficiency and causing internal wear.

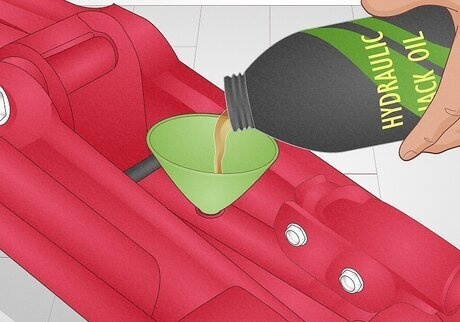

Check oil level every 3–6 months or after heavy use. When topping off, always lower the ram completely on a stable, level surface before removing the fill plug. This prevents aeration and ensures an accurate reading against the reservoir neck.

Choosing manufacturer-specified hydraulic oil safeguards seal compatibility and viscosity at operating temperatures. Remember to use a clean funnel and lint-free cloth to prevent introducing debris.

2. Keep the Jack Clean and Rust-Free

Dust, dirt, and rust can impair moving parts and seals. A clean jack not only looks better but also operates reliably.

Cleaning: Wipe down the exterior with a damp cloth after each use. For stubborn grime, use a mild degreaser, then rinse and dry thoroughly.

Rust Prevention: Apply a light coat of corrosion-inhibiting spray or thin machine oil to all exposed metal surfaces, especially if the jack is stored in a humid environment.

3. Store on a Level, Dry Surface

Proper storage conditions prevent warping, oil leakage, and corrosion.

Surface Requirements: A flat, solid surface (e.g., concrete floor) ensures the jack remains upright and evenly supported.

Environment: Choose a dry area away from direct sunlight and extreme humidity. Elevated humidity accelerates rust formation.

4. Lubrication and Fastener Checks for Smooth Operation

While hydraulic oil handles the heavy lifting, light machine oil or white lithium grease keeps the smaller mechanisms moving freely. Every six months—or more frequently if the jack sees heavy daily use—apply lubricant to the release-valve screw threads, pivot points on the handle socket, and any extension screws. This reduces friction, prevents binding, and ensures consistent response when opening or closing the valve. Concurrently, inspect all bolts, nuts, and fasteners for tightness; vibrations during lifting cycles can loosen them over time. Adhering to the manufacturer's torque specifications prevents stripped threads or warped components.

5. Check for Fluid Leaks Before Each Use

Leakage is a clear sign of seal failure or loose fittings and can lead to jack collapse under load.

Visual Inspection: Examine the base, cylinder, and ram for oil seepage.

Operational Test: Pump the jack without load; if oil bleeds out around seals or fittings, disassemble and replace O-rings or tighten connections as needed.

6. Operate Only on Stable, Flat Ground

Uneven surfaces can shift the load and compromise jack stability, risking damage or injury.

Ground Prep: Clear away gravel, debris, and oil slicks.

Use of Base Plate: If working on soft soil or asphalt, place a sturdy steel or wooden plate beneath the jack to distribute weight evenly.

7. Avoid Overloading Beyond Capacity

Every bottle jack is rated for a maximum lifting weight; exceeding it stresses internal components and voids warranties.

Capacity Label: Always verify the weight rating stamped on the jack.

Safety Margin: Aim to lift no more than 80–90 % of the rated capacity to minimize strain.

8. Bleed Air from the System Properly

Air trapped in the hydraulic circuit leads to spongy pumping action and reduced lifting height.

Bleeding Steps:

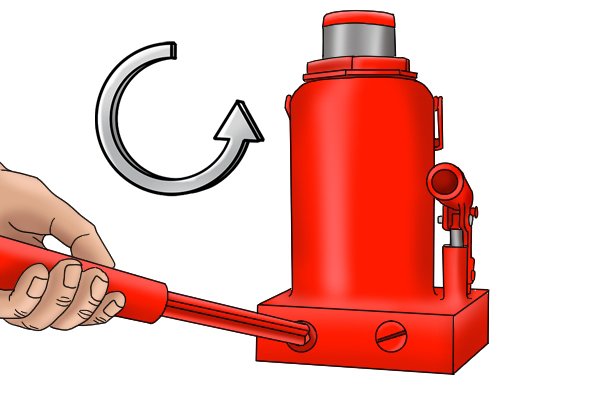

Open the release valve fully.

Pump the handle several times until no air bubbles emerge.

Close the valve and test the jack under light load to confirm firmness.

Best Practice: Bleed whenever the jack has been fully drained for oil change or stored in a vertical position.

Conclusion

Keeping a bottle jack in peak working order is less a chore than a small investment that pays dividends in reliability, safety, and lifespan. By incorporating these ten straightforward practices into your routine, you can trust your jack to perform flawlessly whenever you need it.

Integrate these practices into your seasonal maintenance routine and trust that your bottle jack will rise to every challenge—lifting with power and precision for years to come.